Polyhexanide (PHMB) was first synthesized and characterized by ICI in England in the 1950s in the search for new malaria drugs. It quickly became apparent that polyhexanide was not very effective against malaria, but had a very good antimicrobial effect against a broad germ spectrum .

Polyhexanide has since been successfully used in extremely different concentrations as a disinfectant in industrial processes and as a preservative in cosmetic and medical products.

A selection of Polyhexanide applications:

Preservatives in cosmetics

Medical devices for wound cleansing and MRSA decontamination

Medicament for wound antiseptics

Disinfection solutions for contact lenses

Disinfection of swimming and bathing water

various industrial applications

The Swiss surgeon Prof. Willenegger introduced polyhexanide into human medicine at the end of the 1980s. He used it very successfully under the name Lavasept® for local antiseptic treatment in surgical procedures.

It has been shown that cleansing wounds with products based on the polyhexanide-betaine complex reduces bacterial load and the rate of infection. Polyhexanide additionally influences the healing process of burn wounds positively.

Polyhexanide was registered again by the US Environmental Protection Agency (EPA) in September 2005 for use in various fields. The increasing occurrence of antibiotic resistance in human pathogenic bacteria intensified the search for effective and tolerable local antiseptics, and polyhexanide proved to be an excellently suited substance.

The therapeutic breadth or benefit-risk ratio of polyhexanide is significantly better than that of other antiseptics >..

A significantly improved healing of aseptic wounds could be demonstrated, which could possibly be explained by an inhibition of collagen degradation. In a clinical study on grade IIa burn wounds a analgesic effect of polyhexanide-containing wound dressings was also demonstrated.

The importance of polyhexanide in wound antiseptics is undisputed today. The antimicrobial treatment with polihexanide-containing products has been recommended by leading wound experts as the first choice since 2004 until today.

Polyhexanide

Polyhexanide is a polymeric biguanide with antimicrobial properties and excellent skin and mucous membrane tolerance.

polyhexanide or polyhexamethylene biguanide is listed in the INCI under the name “polyaminopropyl biguanide”. It is used as a preservative and for support of wound healing in medical products as well as in pharmaceuticals.

Since 1959 it has been used for preservation in the cosmetics industry and is approved up to a concentration of 0.3% according to the German Cosmetic Decree (KVO). Thus there is no limitation in the duration of use.

Polyhexanide has been the first choice *for the treatment of acute and chronic wounds since 2004.

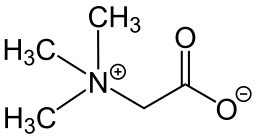

Betaine

Undecylenamidopropyl betaine is a particularly high quality amphoteric surfactant that reduces the surface tension of liquids and thus breaks up biofilms. Due to this wetting power it facilitates the removal of harmful germs.

Betaines have an excellent cleansing effect and at the same time best skin compatibility. This special betaine is approved by the German Cosmetic Decree (KVO) with a concentration of up to 40% in baby shampoos. In contrast to other products, re-lubricating substances can be completely dispensed with as it does not dry out the skin.

THE POLYHEXANIDE-BETAINE COMPLEX

The use of polyhexanide in combination with a surface-active surfactant (betaine) plays a decisive role in skin and wound cleansing >a decisive role. Skin and wound cleansing means the removal of visible impurities and the reduction of bacteria and germs. For a clean skin and/or wound, harmful substances of any kind must be removed.

The polyhexanide-betaine complex has an excellent cleaning effect, is very well tissue compatible and significantly reduces the germ load. Due to the modified surface tension, the solution reaches areas into which water cannot penetrate. This means that even areas of wounds and skin that are difficult to access are cleaned more thoroughly than with conventional cleansers.

In contrast to many other cleaning solutions or antiseptics, does not use alcohol at all , therefore products based on this product are also ideally suited for diabetics and allergy sufferers.

Product properties of the PHMB complex

In concentrations of 0.1% polyhexanide and 0.1% betaine solutions, sprays, mouth rinses, gels and foams have outstanding properties:

- have a high therapeutic breadth with a very broad spectrum of action

- are not absorbed

- are painless to use

- promote wound healing

- are effective even under blood and protein stress

- according to consensus DGfW*, have been the only wound dressing with no restriction on its duration of use since 2004 and 2009

- are suitable for MRSA decontamination

- are not toxic or irritant

- have an excellent skin & mucous membrane tolerance

- exclude the formation of resistances

- have no allergenic potential

- do not dry out the skin

- can be safely stored, transported and handled

according to consensus DGfW*, have been the only wound dressing with no restriction on its duration of use since 2004 and 2009

*= German Society for Wound Healing and Wound Treatment

THERAPEUTIC INDEX

The therapeutic width is the distance between a therapeutic dose and a dose that can lead to a toxic reaction. The higher the therapeutic quotient, the safer the use of a medical device.